Welding Process

ERW · SAW · EFW

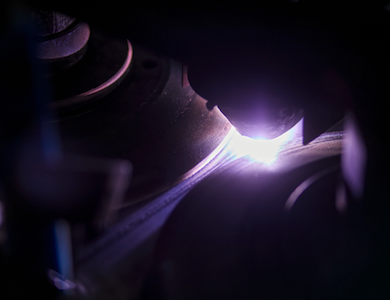

ERW

As we produce steel pipe products of various steel grades and sizes with sound welds through non-destructive testing, SeAH Steel has the largest production capacity and the best technology in Korea. Green products manufactured in safe workplaces serve a wide range of industries.

ERW SIZE RANGE - Carbon

| Product Manufacturing Line | Production Range | Production capacity | Location | ||

|---|---|---|---|---|---|

| Outer diameter(mm) | Thickness(mm) | Length(m) | (tons/year) | ||

| ERW(Round pipe) | 19.0~610.0 | 2.0~25.0 | 4.5~24.4 | 1,000,000 | Pohang |

| ERW(Angular pipe) | 200X200~400X400 | 5.0~12.0 | 5.0~18.3 | ||

| ERW(Round pipe) | 21.0~219.1 | 1.7~10.2 | 4.0~13.7 | 300,000 | Gunsan |

| ERW(Angular pipe) | 150X150 | 3.8~7.8 | 5.5~15.5 | ||

| SRM | 19.0~114.3 | 2.2~15.2 | 4.5~12.8 | 50,000 | Pohang |

| Plating | 21.0~609.6 | - | Max. 8.0 | 150,000 | Gunsan |

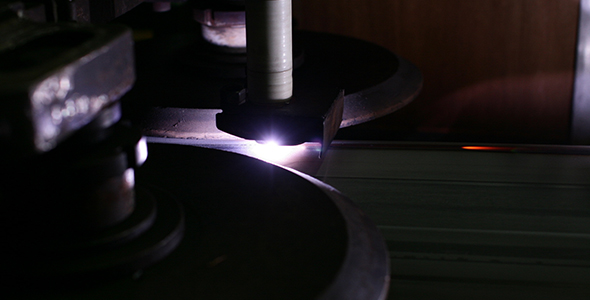

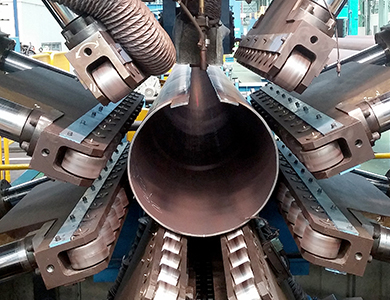

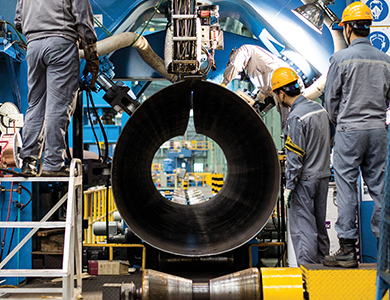

SAW

Based on the welding technology and know-how accumulated at the R&D welding research center, we secure optimal welding conditions and realize the best welding quality by applying a monitoring system. In particular, by applying the expander facility for the first time in Korea, we secure optimal dimensional quality and soundness of welds through non-destructive testing.

SAW SIZE RANGE - Carbon

| Product Manufacturing Line | Production Range | Production capacity | Location | ||||

|---|---|---|---|---|---|---|---|

| Outer diameter(mm) | Thickness(mm) | Length(m) | (tons/year) | ||||

| Press Bending |

JCOE 12M | 457.2~1625.6 | MAX 50.8 | MAX. 12.2 | 60,000 | Pohang | |

| JCOE 18M | 457.2~1625.6 | MAX 50.8 | MAX. 18.3 | 200,000 | Pohang | ||

| JCO 13M | 406.4~1676.4 | MAX 65 | MAX. 13 | 120,000 | Suncheon | ||

| Roll Bending |

|||||||

| RB4M | 1,473.2~6,500 | 150 | MAX. 4.2 | 48,000 | Suncheon | MAX. 105M available | |

| Spiral | No.1 MILL | 406.4~3,048.0 | 6.0~25.4 | MAX. 50 | 60,000 | Suncheon | |

| No.2 MILL | 406.4~4,013.2 | 6.0~25.4 | MAX. 70 | 60,000 | Suncheon | the largest pipe diameter in Korea | |

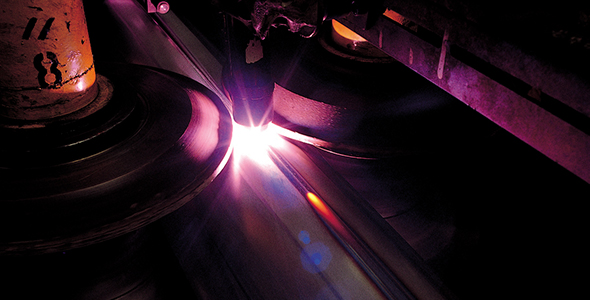

EFW

Continuous technological development in EFW welding (PAW, GTAW, SAW) used in stainless steel pipe production enhances competitiveness in high-quality specialty pipes required for LNG, chemical and refining plants, marine plants (FPSO, etc.), LNG vessels, desalination facilities, and other applications.

EFW SIZE RANGE - STS

| Product Manufacturing Line | Production Range | Production capacity | Location | ||||

|---|---|---|---|---|---|---|---|

| Outer diameter(mm) | Thickness(mm) | Length(m) | (tons/year) | ||||

| Roll Forming | 13.8~406.4 | 12.7 | 13.5 | 37,200 | Changwon | ||

| 406.4~609.6 | 13 | 13 | 10,000 | Suncheon | |||

| Roll Bending | 457.2~2032 | 4.0~25.4 | 6.1 | 6,000 | Suncheon | ||

| Press Bending | 406.4~1,676.4 | 8~65 | 13.2 | 24,000 | Suncheon | ||