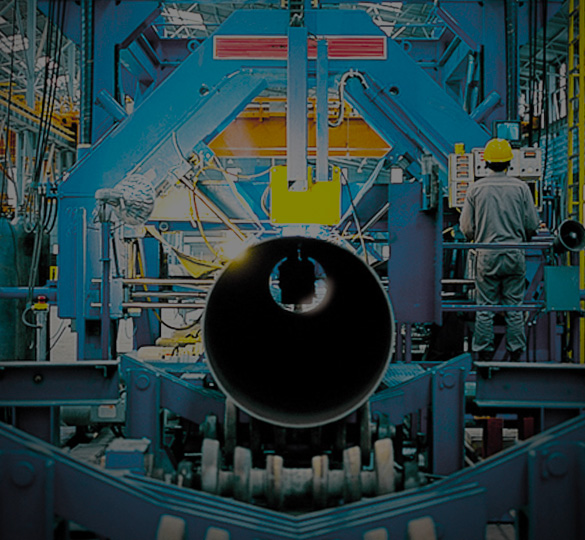

Carbon welded steel pipe

SeAh Steel produces carbon welded steel pipe products with a differentiated production system and strict quality control from manufacturing steel pipe to post-processing and quality inspection

01

Superior technology and quality

ㆍOver 60 years of steel pipe manufacturing technology and know-how

ㆍContinuous material research and technology development through the specialized steel pipe R&D center

02

Broad product supply ability

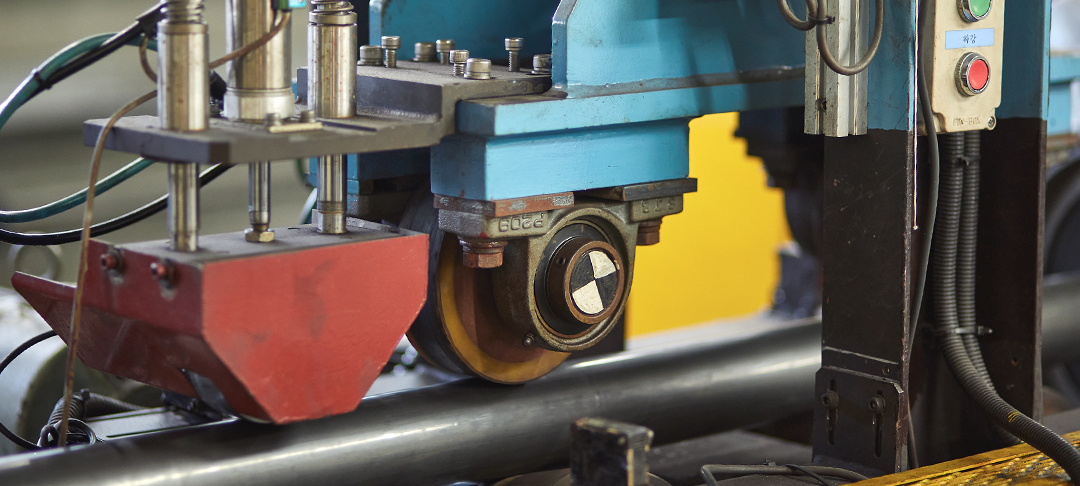

ㆍSteel pipe manufacturing facilities, including ERW, SAW, and SPIRAL, as well as SRM and hot-dip galvanizing facilities, respond to various market needs.

ㆍSecured competitiveness to respond to domestic and overseas project demands by producing finished OCTG products that can perform even post-processing, including QT equipment and CNC screw machines.

03

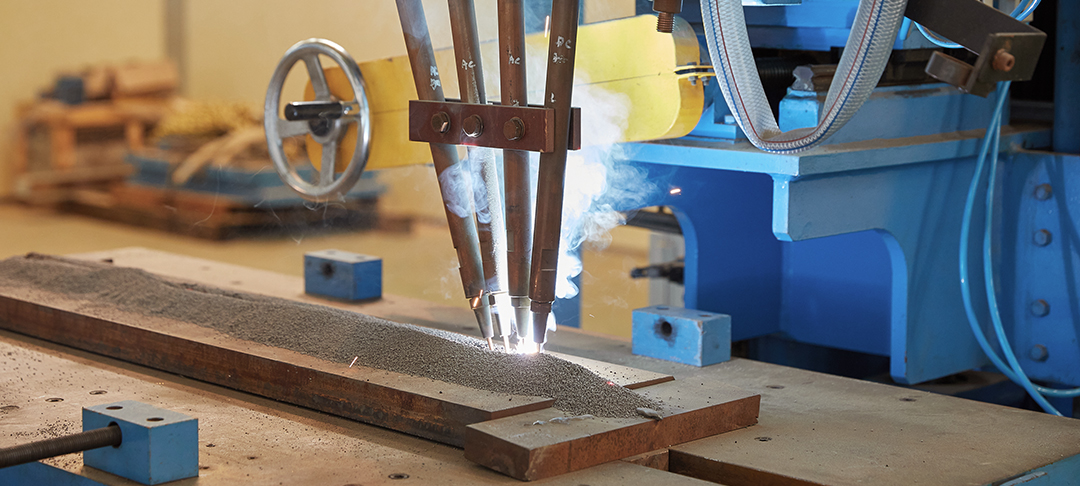

Differentiated production and inspection systems

ㆍControl welding quality with a monitoring system

ㆍDetect welding failures with the latest non-destructive testing equipment

ㆍHighest welding quality assurance with product testing services provided by an ISO 17025 accredited testing laboratory

Featured Products

-

ERW

ㆍOuter Diameter : 19.0~610.0mm

ㆍThickness : 2.0~25mm

ㆍLength : 24.4m

ㆍProduction Capacity : 1,300,000tons

-

SAW, Press Bending

ㆍOuter Diameter : 406.4~1676.4mm

ㆍThickness : 8.0~65.0mm

ㆍLength : 18.3m

ㆍProduction Capacity : 380,000tons

-

SAW, Roll Bending

ㆍOuter Diameter : 1473.2~6500mm

ㆍThickness : 150mm

ㆍLength : 4.2m

ㆍProduction Capacity : 48,000tons

-

SAW, Spiral Line

ㆍOuter Diameter : 406.4~4013.2mm

ㆍThickness : 25.4mm

ㆍLength : 70m

ㆍProduction Capacity : 120,000tons

Detailed Usage

-

For OIL & GAS

ㆍLinepipe

ㆍOCTG

-

For Heat Exchangers

ㆍBoiler water, smoke, superheat, and air preheat pipes

ㆍExchange tubes, condenser tubes, and catalyst tubes for heat exchangers in the chemical industry

-

For Plumbing

ㆍSPP (carbon steel pipes for ordinary piping) or galvanized steel pipe for general piping, water storage, sewer, industrial, irrigation, water storage, fire hydrants, ship piping, and oil and gas transportation

ㆍSteel pipe for plumbing water, oil, gas, steam, air, etc., with low working pressure

ㆍSteel pipe for pressure piping used at 350 degrees or less

-

For Structure

ㆍStructural steel pipes used for structures, bridges, ports, machinery, pylons, automobiles, bicycles, power poles, steel pipe scaffolds, fixtures, supports, handrails, fences, etc.

ㆍSteel pipe piles, steel pipe piles for piles in civil, architectural, and other structures

-

Conduit

ㆍRigid steel conduits to protect electrical wiring and electrical wiring

-

For Insulation

ㆍFor district heating plumbing, heat and cold insulation, freeze prevention plumbing, and self-heating insulated double pipes

-

Material conduit

ㆍFor automotive use

Demand Industry

Packaging Specification

Bundle packing

Secure the product with a steel band

Plastic packing

Prevent internal moisture and debris from entering

PP rope packing

Prevent collisions between products

PP Hessian packing

Corrosion prevention

Cross Steel Bar packing

Outer diameter deformation prevention

Bevel Protector packing

Protecting the pipe end