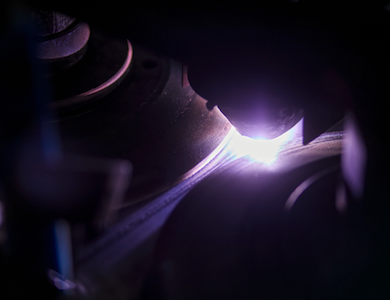

Welding Process

ERW · SAW · EFW · High pulsed GTAW

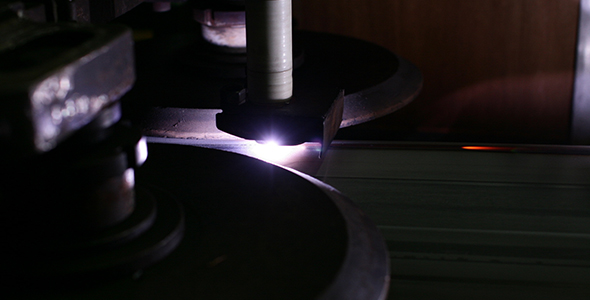

ERW

As we produce steel pipe products of various steel grades and sizes with sound welds through non-destructive testing, SeAH Steel has the largest production capacity and the best technology in Korea. Green products manufactured in safe workplaces serve a wide range of industries.

ERW SIZE RANGE - Carbon

| Product Manufacturing Line | Production Range | Production capacity | Location | ||

|---|---|---|---|---|---|

| Outer diameter(mm) | Thickness(mm) | Length(m) | (tons/year) | ||

| ERW(Round pipe) | 19.0~610.0 | 2.0~25.0 | 4.5~24.4 | 1,000,000 | Pohang |

| ERW(Angular pipe) | 200X200~400X400 | 5.0~12.0 | 5.0~18.3 | ||

| ERW(Round pipe) | 21.0~219.1 | 1.7~10.2 | 4.0~13.7 | 300,000 | Gunsan |

| ERW(Angular pipe) | 150X150 | 3.8~7.8 | 5.5~15.5 | ||

| SRM | 19.0~114.3 | 2.2~15.2 | 4.5~12.8 | 50,000 | Pohang |

| Plating | 21.0~609.6 | - | Max. 8.0 | 220,000 | Gunsan |

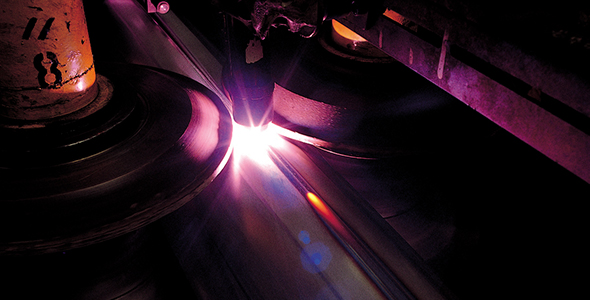

SAW

Based on the welding technology and know-how accumulated at the R&D welding research center, we secure optimal welding conditions and realize the best welding quality by applying a monitoring system. In particular, by applying the expander facility for the first time in Korea, we secure optimal dimensional quality and soundness of welds through non-destructive testing.

SAW SIZE RANGE - Carbon

| Product Manufacturing Line | Production Range | Production capacity | Location | ||||

|---|---|---|---|---|---|---|---|

| Outer diameter(mm) | Thickness(mm) | Length(m) | (tons/year) | ||||

| Press Bending |

JCOE 12M | 457.2~1625.6 | MAX 50.8 | MAX. 12.2 | 60,000 | Pohang | |

| JCOE 18M | 457.2~1625.6 | MAX 50.8 | MAX. 18.3 | 200,000 | Pohang | ||

| JCO 13M | 406.4~1676.4 | MAX 65 | MAX. 13 | 120,000 | Suncheon | ||

| Roll Bending |

|||||||

| RB4M | 1,473.2~6,500 | 150 | MAX. 4.2 | 48,000 | Suncheon | MAX. 105M available | |

| Spiral | No.1 MILL | 406.4~3,048.0 | 6.0~25.4 | MAX. 50 | 60,000 | Suncheon | |

| No.2 MILL | 406.4~4,013.2 | 6.0~25.4 | MAX. 70 | 60,000 | Suncheon | the largest pipe diameter in Korea | |

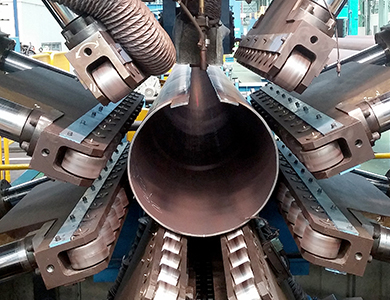

EFW

Continuous technological development in EFW welding (PAW, GTAW, SAW) used in stainless steel pipe production enhances competitiveness in high-quality specialty pipes required for LNG, chemical and refining plants, marine plants (FPSO, etc.), LNG vessels, desalination facilities, and other applications.

EFW SIZE RANGE - STS

| Product Manufacturing Line | Production Range | Production capacity | Location | ||||

|---|---|---|---|---|---|---|---|

| Outer diameter(mm) | Thickness(mm) | Length(m) | (tons/year) | ||||

| Roll Forming | 13.8~406.4 | 12.7 | 13.5 | 37,200 | Changwon | ||

| 406.4~609.6 | 13 | 13 | 10,000 | Suncheon | |||

| Roll Bending | 457.2~2032 | 4.0~25.4 | 6.1 | 6,000 | Suncheon | ||

| Press Bending | 406.4~1,676.4 | 8~65 | 13.2 | 24,000 | Suncheon | ||

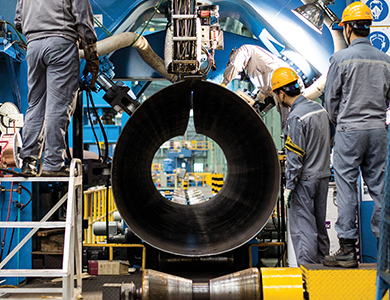

High pulsed GTAW

We produce high-quality tubes for heat exchangers supplied to nuclear power plants and other facilities using high pulsed GTAW welding, ensuring excellent corrosion resistance and high strength. Leveraging this expertise, we are capable of producing tubes not only in titanium but also pioneering domestically in the production of Super Austenitic (SR50A) tubes.

TUBE SIZE RANGE - STS, Ti

| Product Manufacturing Line | Production Range | Production capacity | |||||

|---|---|---|---|---|---|---|---|

| Outer diameter(mm) | Thickness(mm) | Length(m) | |||||

| STS Tube | 15.8~60.5 | 0.5 ~ 3.5 | Max. 20 | 2,200 | Changwon | ||

| Ti Tube | 15.8~60.5 | 0.5 ~ 3.5 | Max. 20 | 1,500 | |||