Follow-up processes

SRM, Q/T, Plating, and Threading

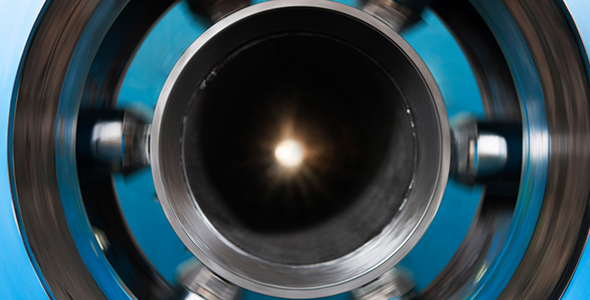

SRM

The parent pipe manufactured by electric resistance welding is subjected to subsequent processes such as induction heating and size control through a centralized automatic control system to produce the small outer diameter, ultra-thick, bead-free product desired by the customer. A homogeneous, FULL-BODY heat treatment ensures the weld is sound with properties equivalent to the parent tube.

SRM SIZE RANGE

| Product Manufacturing Line | Production Range | Production capacity | Location | ||

|---|---|---|---|---|---|

| Outer diameter(mm) | Thickness(mm) | Length(m) | (tons/year) | ||

| SRM | 19.0~114.3 | 2.2~15.2 | 4.5~12.8 | 50,000 | Pohang |

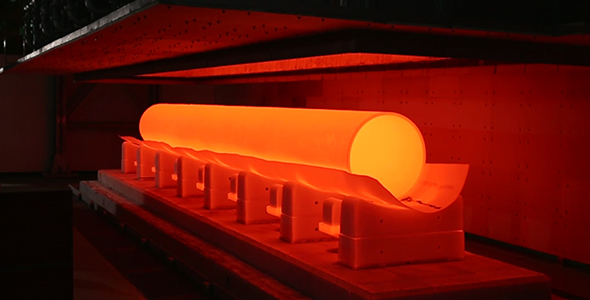

Q/T

The mother pipe, manufactured by electric resistance welding, is subjected to quenching and tempering heat treatment by a centralized, automated control system to upgrade it to a high-strength product reliably used in harsh mining environments. Through homogeneous heat treatment, ensuring the integrity of the welded joints with properties equivalent to those of the mother pipe, we simultaneously conduct non-destructive testing to ensure quality reliability.

Plating

Melting zinc galvanized products are deposited in a galvanizing bath after the surface of the black tube has been degreased, acid-dipped, rinsed, and FLUXed. After a period, the products lifted from the galvanized bath go through the BLOWING process to a smooth surface on the outside and inside. The resulting product is called white pipe and is used in various applications requiring corrosion resistance.

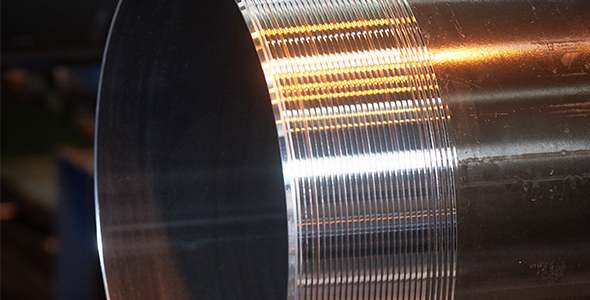

Threading

In addition to machining thread and couplings for regular API 5CT, we also machine and provide our customers with semi-premium connection for use in harsher mining environments. By using state-of-the-art CNC machines, the threads and couplings feature excellent dimensional accuracy and superior leak resistance with Power-Tight engagement.