Welding Process

SAW · Full Leg (Jacket) · Pin Pile · Subassemblies - Leg, Brace (Jacket) · Node, Stub, Cone, Cutting

SAW

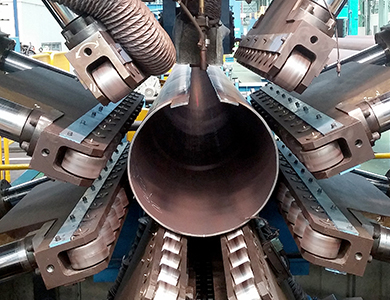

Based on the welding technology and know-how accumulated at the R&D welding research center, we secure optimal welding conditions and realize the best welding quality by applying a monitoring system. In particular, by applying the expander facility for the first time in Korea, we secure optimal dimensional quality and soundness of welds through non-destructive testing.

SAW SIZE RANGE - Carbon

| Product Manufacturing Line | Production Range | Production capacity | Location | ||||

|---|---|---|---|---|---|---|---|

| Outer diameter(mm) | Thickness(mm) | Length(m) | (tons/year) | ||||

| Press Bending |

JCOE 12M | 457.2~1625.6 | MAX 50.8 | MAX. 12.2 | 60,000 | Pohang | |

| JCOE 18M | 457.2~1625.6 | MAX 50.8 | MAX. 18.3 | 200,000 | Pohang | ||

| JCO 13M | 406.4~1676.4 | MAX 65 | MAX. 13 | 120,000 | Suncheon | ||

| Roll Bending |

|||||||

| RB4M | 1,473.2~6,500 | 150 | MAX. 4.2 | 48,000 | Suncheon | MAX. 105M available | |

| Spiral | No.1 MILL | 406.4~3,048.0 | 6.0~25.4 | MAX. 50 | 60,000 | Suncheon | |

| No.2 MILL | 406.4~4,013.2 | 6.0~25.4 | MAX. 70 | 60,000 | Suncheon | the largest pipe diameter in Korea | |

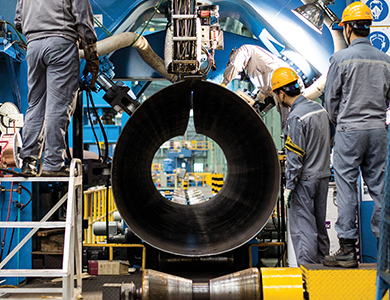

Full Leg (Jacket)

We manufacture Full Legs that compose the jackets for offshore wind substructures.

By delivering these legs combined with nodes, we can help reduce construction costs and time for our clients.

Pin Pile

We manufacture Pin Pile finished products tailored to meet various customer requirements,

such as outer diameter, thickness, and length.

Subassemblies - Leg, Brace (Jacket)

We manufacture Legs and Braces that compose the Jacket by connecting products of various shapes and sizes.

Node, Stub, Cone, Cutting

We manufacture Nodes and Stubs that connect Legs and Braces in Jackets.

We produce Cones that connect steel pipes with different outer diameters.

Additionally, we perform cutting operations (saddle, taper, angle) to accommodate various Jacket designs.